3PC Stainless Steel Threaded Ball Valve 2000PS

Size Range

1/4“ to 2”

Body Materials

A351 CF8M / A216 WCB

Temperature Range

'-50℉ to 450℉ (-46℃ to 232℃)

Stem Materials

A182 F316

Maximum Allowable Operating Pressure

2000 PSI (WOG)

Seat Materials

Delrin / Peek

Body Style

Three Piece

Ball Materials

A182 F316

End Connections

Threaded ASME B1.20.1 NPT

Design Standard

ASME B16.34 , MSS SP-110

Ports

Full Port

Testing Standard

MSS-SP72,API 598

Applications

General Service, Air, Water, Oil & Gas

Face to Face

Manufacturers Standard

Description

Product Attributes

Model No.: 1531

Brand: ZQV

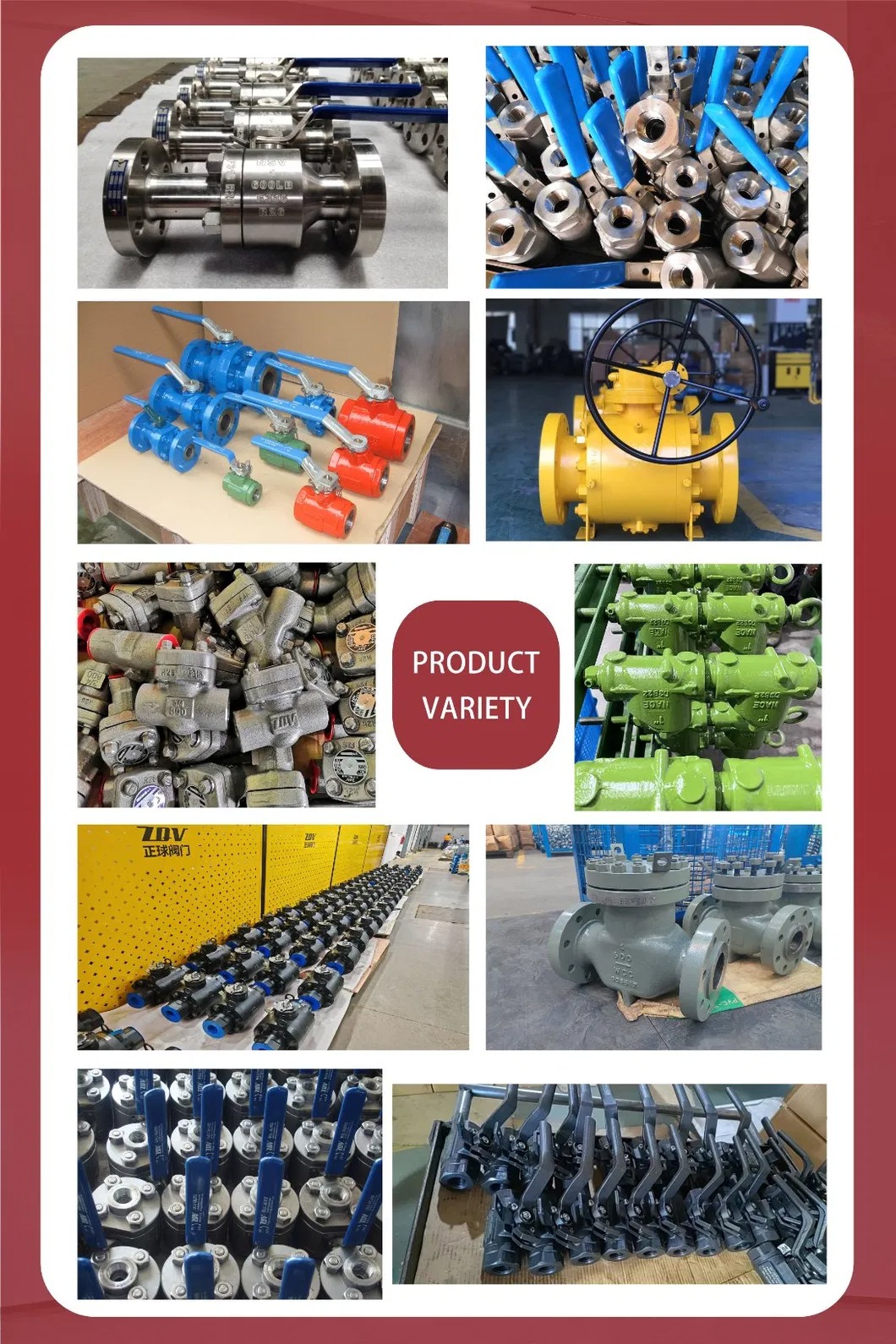

Types Of: Ball Valves

Support Customization: Oem

Place Of Origin: China

Application: General

Medium Temperature: Medium Temperature

Power: Manual

Flow Medium: Oil, Water, Gas

Structure: Ball

Body Construction: 3pc investment casting

End: SW,Threaded,BW

Product Description

Type:Series 1531

●PORTS:Full/Standard

●BODY STYLE:Three Piece

●SIZE RANGE:Full Port: 1/4" - 4" (8mm - 100mm)

●Standard Port: 3/4" - 2.5" (19mm - 65mm)

●TEMPERATURE RANGE:-50°F to 550°F (-46°C to 287°C)

●PRESSURE RATINGS:2200 psi CWP (151 Bar)

●END CONNECTIONS:Threaded, Socket Weld, Butt Weld, Flanged 600#, Extended Socket Weld, Extended Butt Weld

●BODY MATERIALS:Stainless Steel, Carbon Steel, Special Alloys

●SEAT MATERIALS:Standard: TFM 1600

Optional: PEEK, UHMWPE, RPTFE

●APPLICATIONS:Process, Steam, Fire Safe, Industrial Gases, Severe Service

THREE PIECE Ball Valve

1531 Series Ball Valves feature live loaded stem seals and a redundant body seal design. Available in full and standard port models, these rugged, high pressure three piece valves are ideal for process, severe service, high temperature, and high cycle applications.

Secure Mount: 1531 Series valves offer ease of automation due to an integrally cast actuator mounting pad that complies with ISO 5211 standards through 2" valve sizes.

3 PIECE VALVE DESIGN

The three piece body design of the 1531 Series offers many advantages, including installation flexibility, elimination of the need for two sets of flanges, and ease of in line and out of line servicing. These time-saving features are beneficial for process industries, automated valves and welded piping systems by reducing costly downtime. During maintenance, the actuator and accessories can remain mounted on the valve body. The entire valve and actuator assembly is easily reinstalled with no need for recalibration of the unit.

In Line Servicing: To perform in line maintenance, remove the body bolts on opposing sides of the center body, loosen the 2 bolts at the top of the valve and swing the body up. The valve can swing to the left or right depending on which bolts are removed. All body components can be serviced in this position without disturbing the piping system.

Out-of-Line Servicing: For complete removal of valve from the line, remove all body bolts, then lift the valve body out of the pipeline. The removed body can be serviced or replaced, then reinstalled without needing to realign the end connections or the piping system

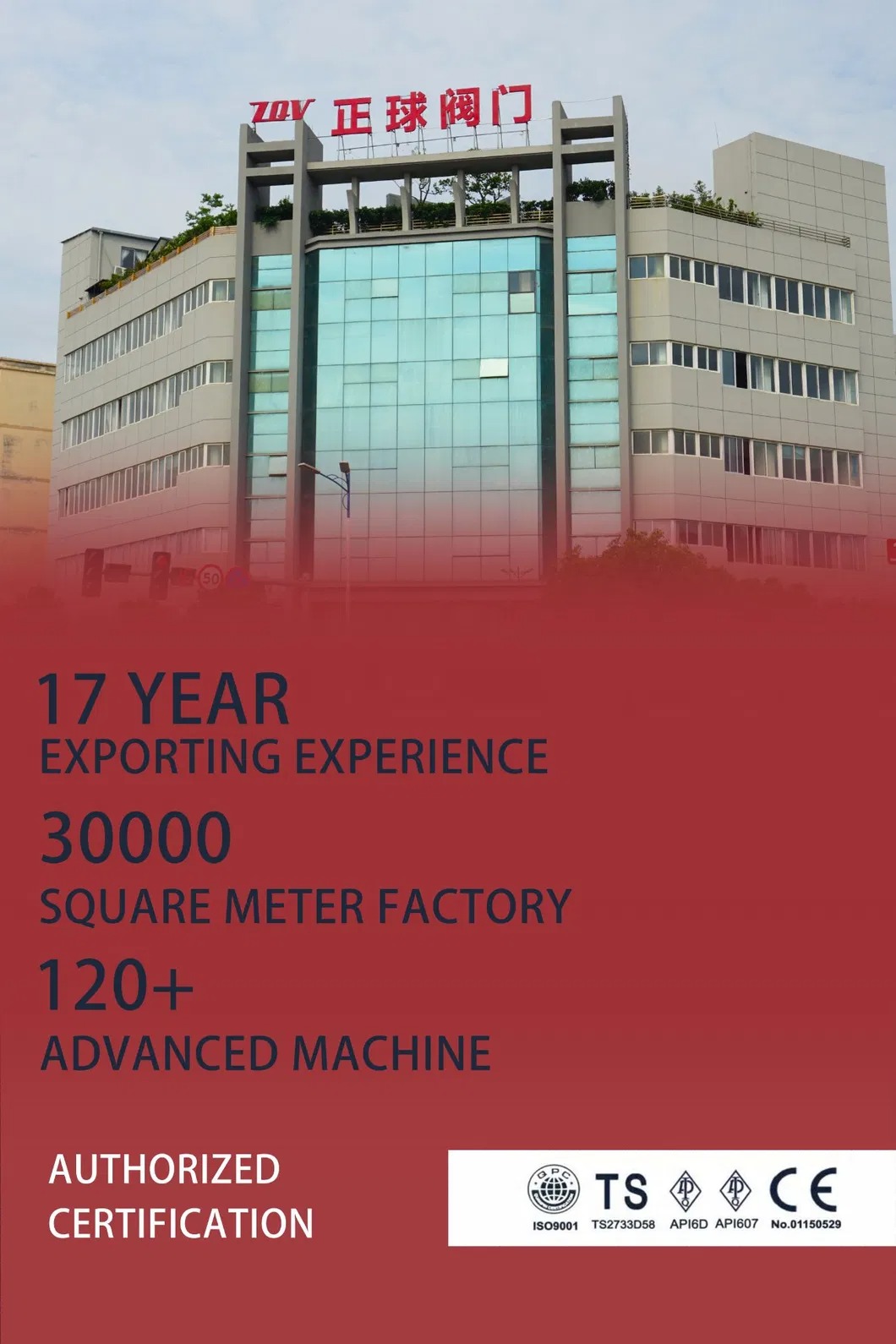

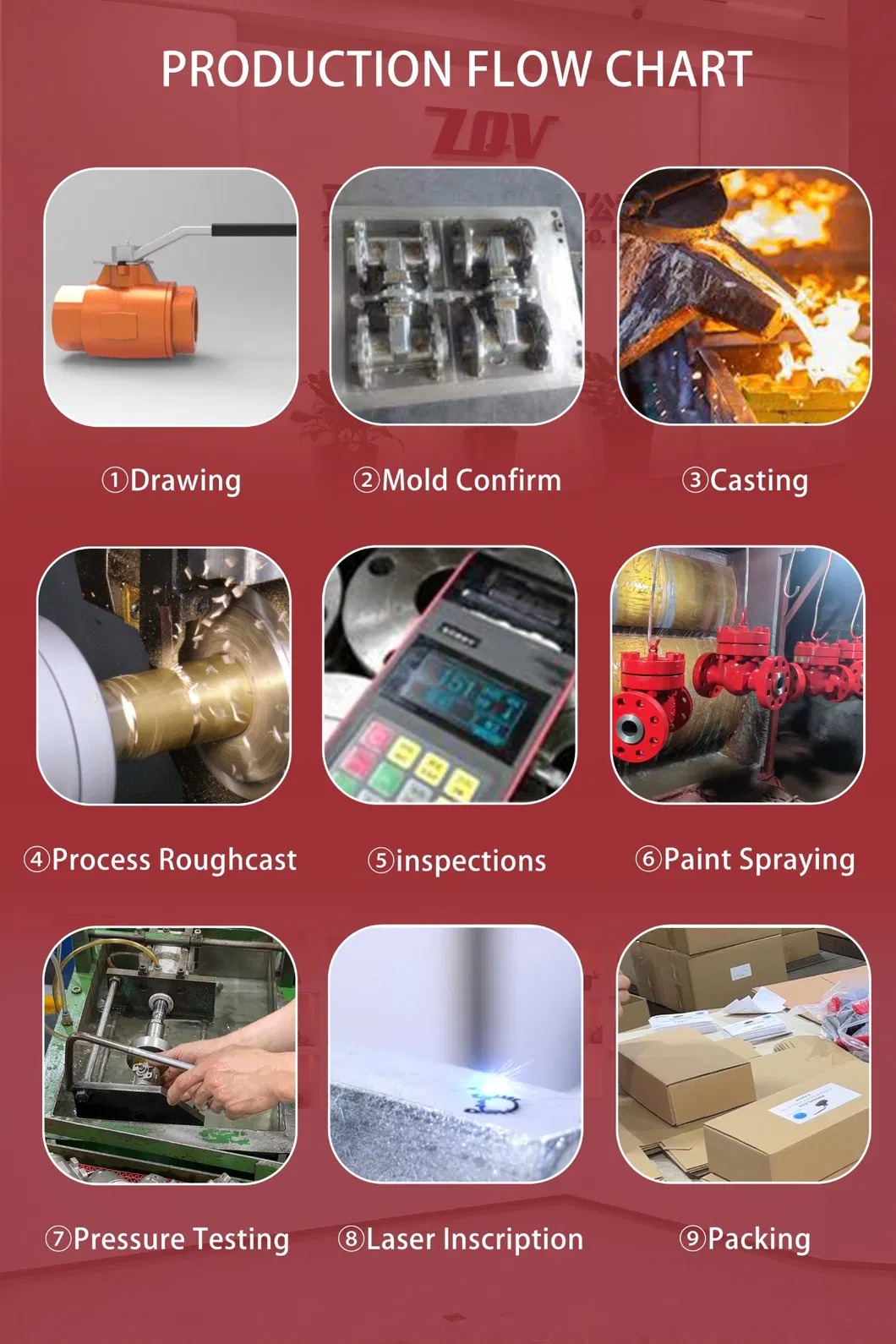

Factory Show