Floating Top Entry Ball Valve

Size Range

2" to 6”

Design Standard

ASME B16.34 , ASME B16.5 , API 6D

Testing Standard

MSS-SP72,API 598

End Connections

ASME B16.5

Face to Face

ASME B16.10

Body Materials

A351 CF8M / A216 WCB

Temperature Range

'-50℉ to 450℉ (-46℃ to 232℃)

Stem Materials

SS304 / SS316

Maximum Allowable Operating Pressure

150LB-2500LB

Seat Materials

PTFE , RPTFE,PEEK,DELRIN

Body Style

Top Entry

Ball Materials

SS304 / SS316

Ports

Full Port / Reduced Port

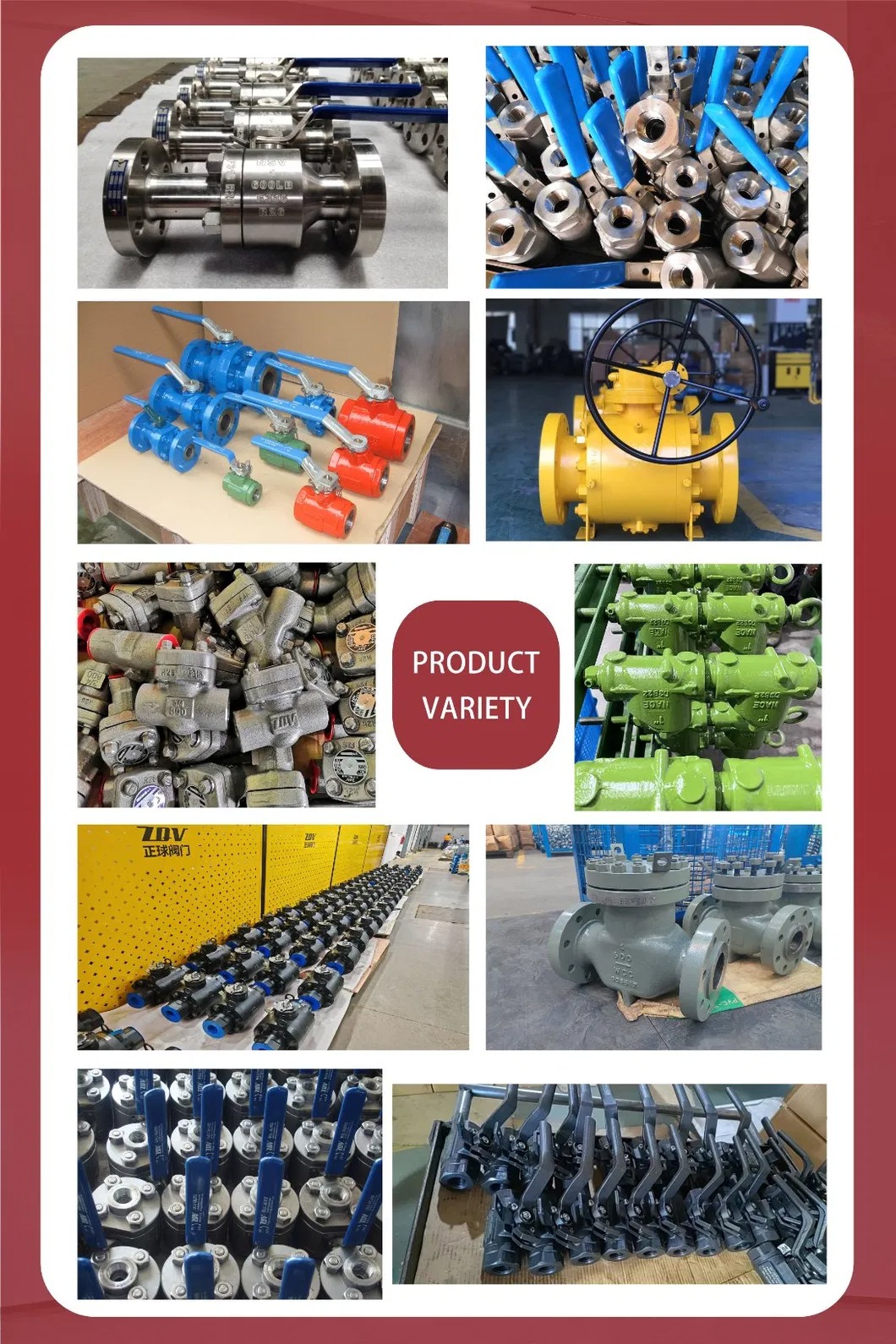

Applications

General Service, Air, Water, Oil & Gas

Description

Integral structure

The body adopts the integral structure, so as to ensure that it has enough strength and rigidity under the maximum rated working pressure. The valve trims have been carefully designed and selected to ensure reliability under various service conditions. The sufficient wall thickness and the connection bolts of high strength are very helpful to the maintenance and servicing of valves and are able to endure pipelines stress.

Structure

The vale adopts the top entry structure. The most distinctive difference between this kind of valve and others is that the online maintenance function can be realized without the need of removing the valve from the pipeline. The seat adopts the concession type seat structure, and the rear end of the seat retainer is set as oblique angle to prevent impurities accumulated on the seat from influencing the concession of seat.

Technical parameter

Nominal diameter:NPS: 2~NPS 56

Operating temperature: -46℃~121℃

Operating pressure: CLASS 150~CLASS 2500

Material: WCB、A105、LCB、LF2、CF8、F304、CF8M、F316, etc.

Design standard: API 6D、ISO 17292

Structural length: ASME B16.10

Connecting end: ASME B16.5、ASME B16.25

Test standard: API 598、API 6D

Operation method: Manual, worm, pneumatic and electric

Application fields: Water, petroleum and natural gas

Factory Show