Power Station Gate Valve

Size Range

1/2"-24"

Materials Grades

WCB, A105N, LCC, LF2, CF8M, 316, 316L, A20, Hastelloy C, Other materials

Pressure Range

Class 150/300/600/900/1500

Trim Materials

TRIM 1,5,8,12,16 & Special Materials

Design Standard

API 600,API 603,API 602,DIN 3352,EN 1984,GOST 3325,BS 1414

Testing Standard

API 598,DIN 3230,EN 12266-1,GOST 9544,BS 6755-1,BS EN 12266-1,BS 5146

End Connections

Raised Face, RTJ, Threaded, Socket Weld, Threaded X Socket Weld

Face to Face

ASME B16.10,EN 558-1,GOST 9544,BS EN 558-1,DIN 3202

Options

NACE, Bevel Gears, Actuation Ready Mounting Pads, Thermal Relief DTR Systems, Double Lead Stem for Quick Run Time

Features

OS&Y, Rising Stem, Flexible Wedge, olted Bonnet, Packing & Gasket (Low Fugitive Emission)

Description

The pressure seal valves are designed in accordance with API600 and ASME B16.34 for service of high temperature and high pressure and are widely used in fossil fuel power plant. Compared with bolted bonnet joint valves, it provides absolute reliable sealing of the bonnet joint, so that the pressure seal valves are more compact and rigid as well as maintenance cost-effective at high temperature and high pressure service.

This kind of gate valve is not only characterized as simple structure and reliable usage, but also able to create slight flexible deformation to compensate the deviation of the sealing face angle generated during processing, thus improving the process performance. In addition, at seat and gate disc seal surface are over-lay with iron-base alloy or Co-base alloy or carbide alloy for long duration.

Technical Specification

Normal Size Range: 2"-24"

Normal Pressure Rating: PN100~PN420, CLASS600~2500

Material: WCB,LCB,WC6, WC9, CF8,CF8M,CF3,CF3M

Temperature Range: -29~425Degree C

Standards compliance

Design and Manufacture:AMSI B16.34,API600 API6D,BS1414

Face to face(end to end):ANSI B16.10,API6D

Flanged cnnection:ANSI B16.5

Butt welded end:ANSI B16.25

Test and inspection:API598,API6D

A.Back up ring:Absors thrust applied by internal pressure

B.Thrust ring:Protects the soft metallic gasket from deformation

C.Gasket:Unique angular design provides superior sealing

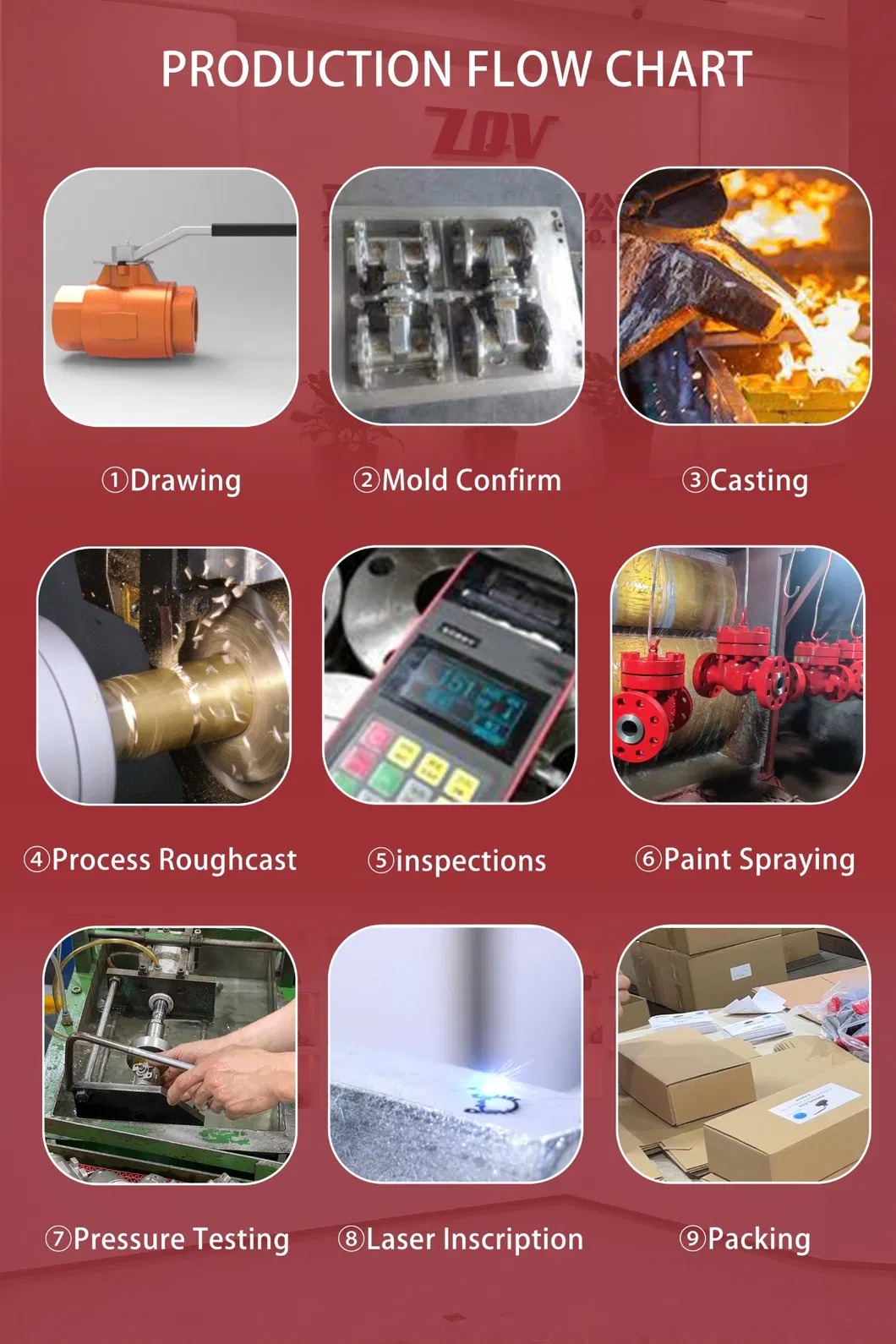

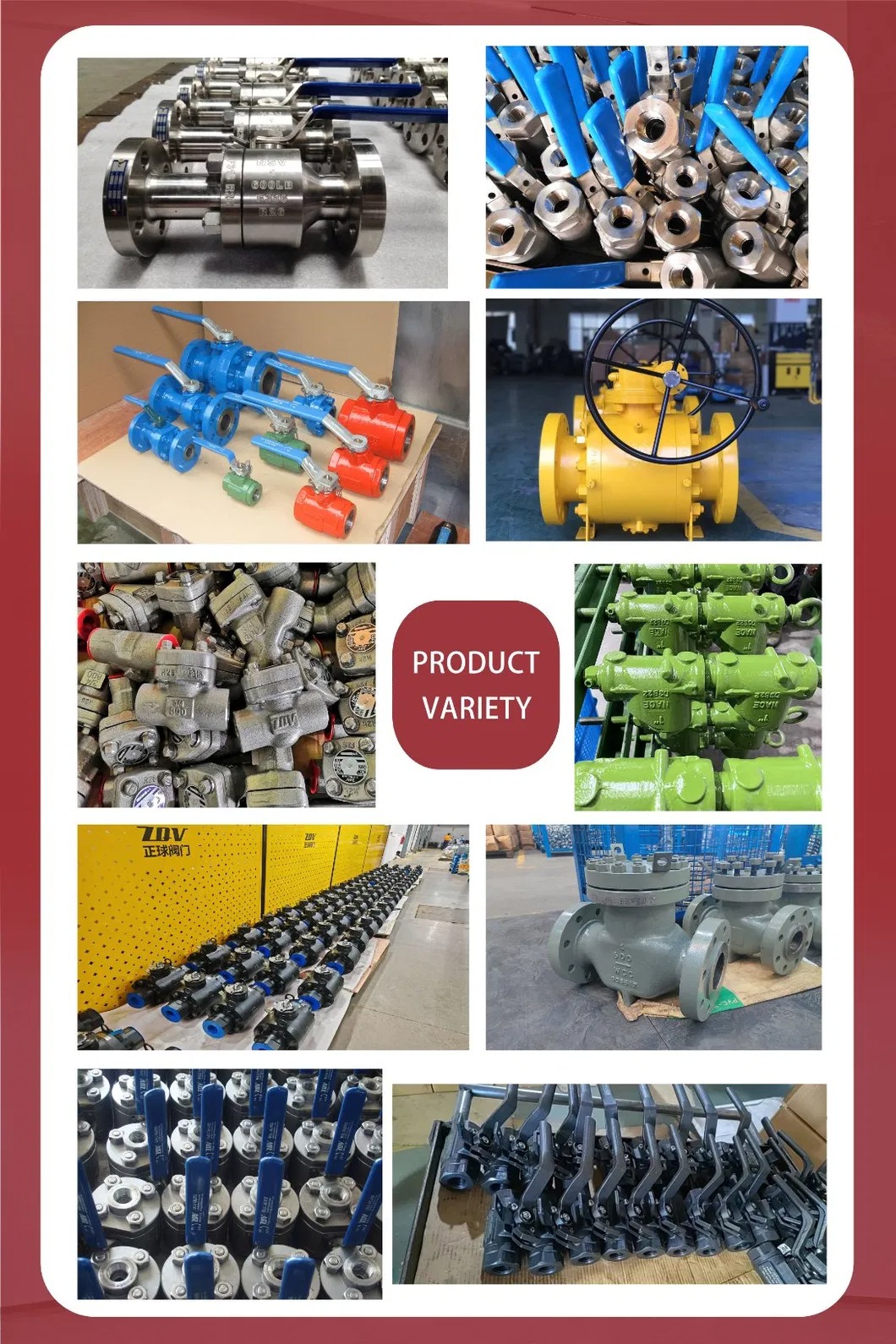

Factory Show