Pneumatic Control Valve

Size Range

1/4“ to 2”

Body Materials

A351 CF8M / A216 WCB

Temperature Range

'-50℉ to 450℉ (-46℃ to 232℃)

Stem Materials

A182 F316

Maximum Allowable Operating Pressure

3000 PSI (WOG)

Seat Materials

Delrin / Peek

Body Style

Two Piece

Ball Materials

A182 F316

End Connections

Threaded ASME B1.20.1 NPT

Design Standard

ASME B16.34 , MSS SP-110

Ports

Full Port

Testing Standard

MSS-SP72,API 598

Applications

General Service, Air, Water, Oil & Gas

Face to Face

Manufacturers Standard

Description

Product structure and features

» Valve core shape structure

It is mainly considered according to the selected flow characteristics and unbalanced force.

» Wear resistance

When the fluid medium is a suspension containing high concentration of abrasive particles, the internal material of the valve shall be hard.

» Corrosion resistance

As the medium is corrosive, the valve with simple structure shall be selected as far as possible.

» Temperature and pressure of medium

When the temperature and pressure of the medium are high and change greatly, the valve whose material of valve core and valve seat is less affected by the change of temperature and pressure shall be selected. When the temperature is ≥ 250 ℃, a radiator shall be added.

» Prevent flash and cavitation

Flash and cavitation occur only in liquid media. In the actual production process, flashing and cavitation will form vibration and noise and shorten the service life of the valve. Therefore, when selecting the valve, the valve shall be prevented from flashing and cavitation.

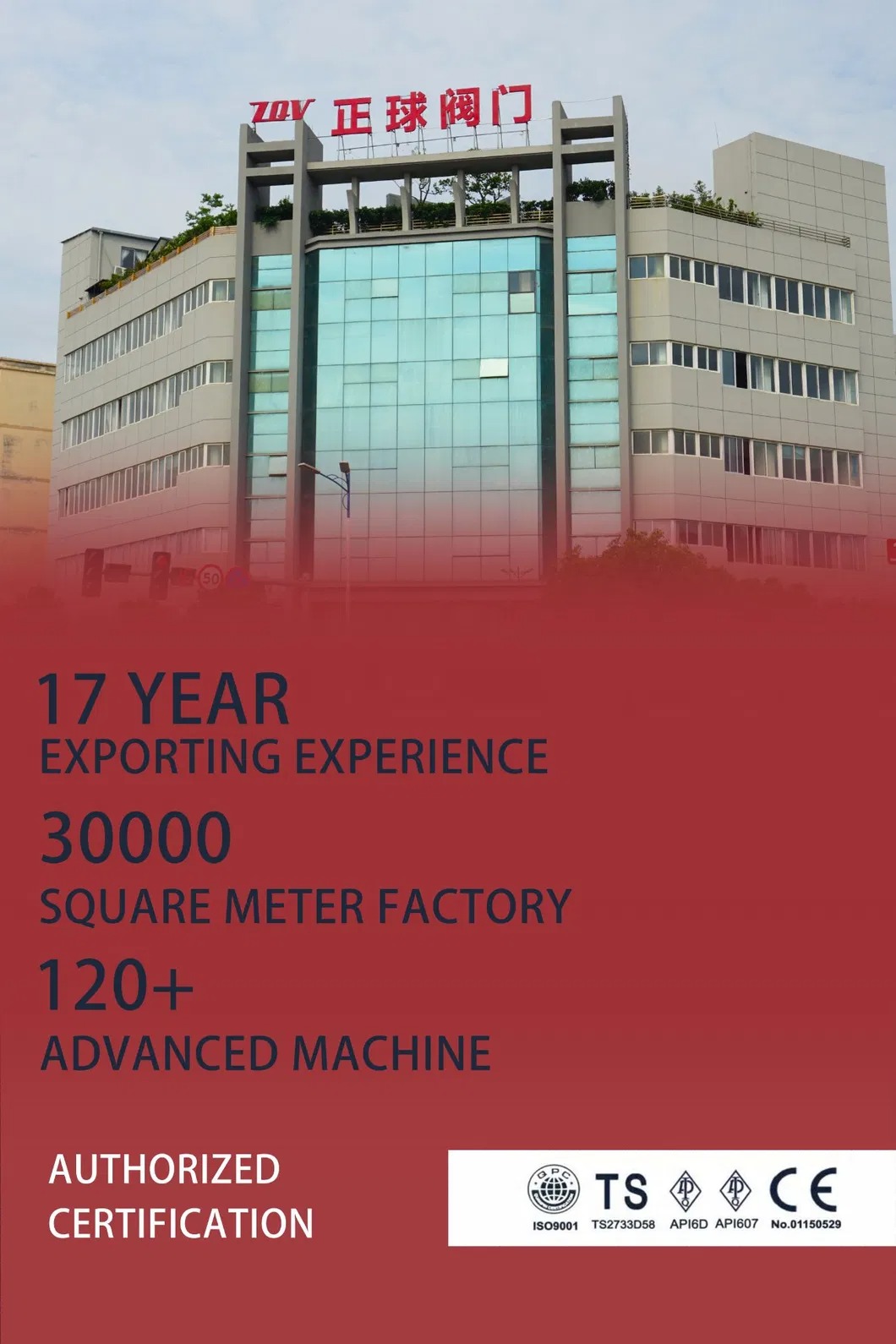

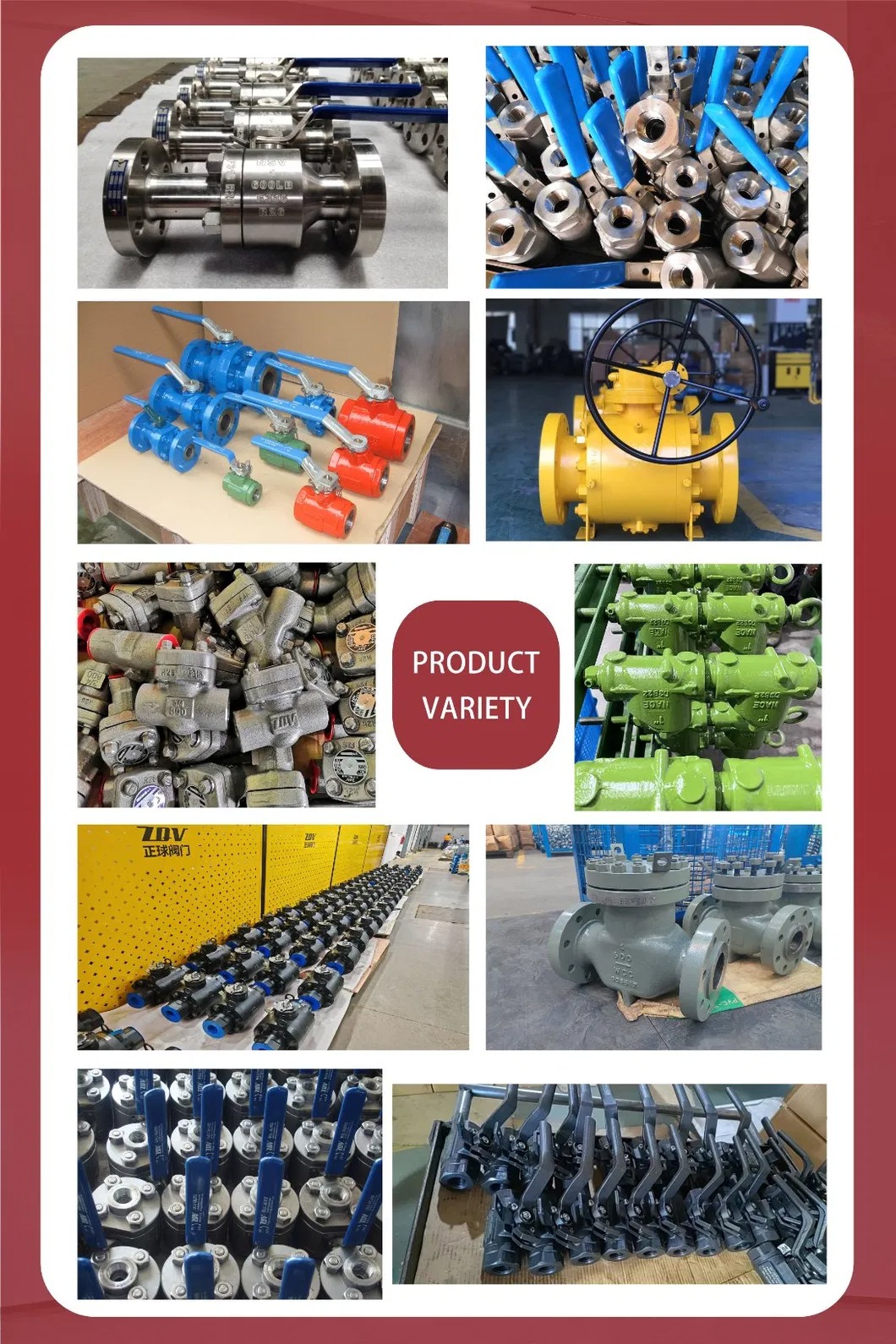

Factory Show