Solenoid Control Valve

Size Range

1/4“ to 2”

Body Materials

A351 CF8M / A216 WCB

Temperature Range

'-50℉ to 450℉ (-46℃ to 232℃)

Stem Materials

A182 F316

Maximum Allowable Operating Pressure

3000 PSI (WOG)

Seat Materials

Delrin / Peek

Body Style

Two Piece

Ball Materials

A182 F316

End Connections

Threaded ASME B1.20.1 NPT

Design Standard

ASME B16.34 , MSS SP-110

Ports

Full Port

Testing Standard

MSS-SP72,API 598

Applications

General Service, Air, Water, Oil & Gas

Face to Face

Manufacturers Standard

Description

Product installation

» During installation, the arrow on the valve body shall be consistent with the flow direction of the medium. Do not install it where there is direct dripping or splashing. The solenoid valve shall be installed vertically upward;

» The solenoid valve shall ensure normal operation within the fluctuation range of 15% - 10% of the rated voltage;

» After the solenoid valve is installed, there shall be no reverse differential pressure in the pipeline. It needs to be powered on several times to make it suitable for temperature before it can be officially put into use;

» The pipeline shall be thoroughly cleaned before the installation of solenoid valve. The medium introduced shall be free of impurities. Filter installed in front of valve;

» When the solenoid valve fails or is cleaned, a bypass device shall be installed to ensure the continuous operation of the system.

Technical parameter

» Switch type: normally closed NC (power off, power on and on); Normally open no (optional)

» Medium temperature: - 5 ℃ ~ + 80 ℃

» Ambient temperature: - 10 ℃ ~ + 50 ℃

» Flow direction: unidirectional flow

» Medium viscosity: ≤ 20cst

» Valve body material: 304 / CF8 stainless steel and magnetic conducting stainless steel

» Sealing material: nitrile rubber NBR

» Electrical connection: junction box din43650

» Rated voltage and power: DC 24V ± 10% (power 13W)

» Protection grade: IP65

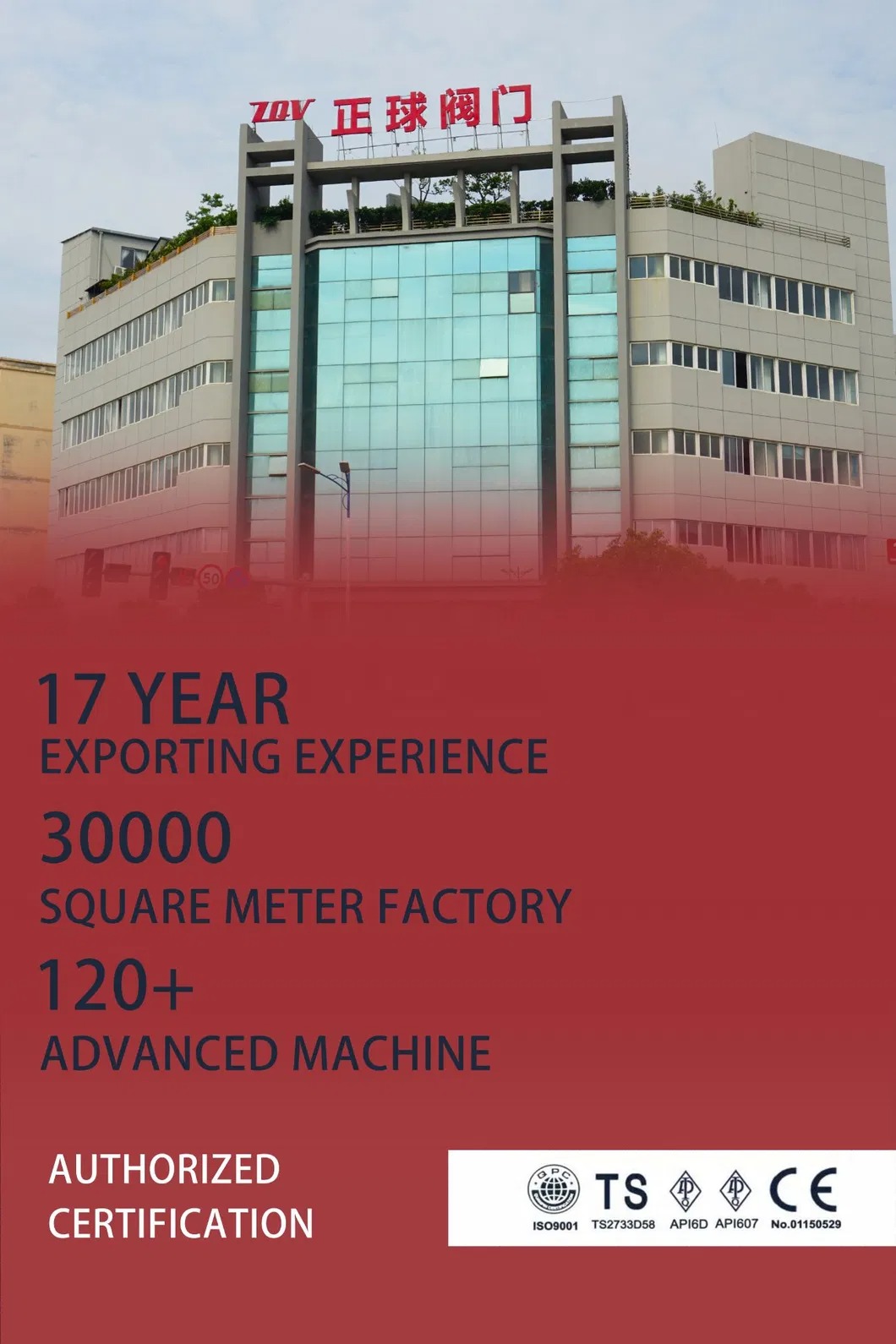

Factory Show