Forged Bellow Sealed Globe Valve

Size Range

1/2"-24"

Materials Grades

WCB, A105N, LCC, LF2, CF8M, 316, 316L, A20, Hastelloy C, Other materials

Pressure Range

Class 150/300/600/900/1500

Trim Materials

TRIM 1,5,8,12,16 & Special Materials

Design Standard

BS 1873 ,DIN EN 13709,GOST 3326,API 623,API 603,API 602

Testing Standard

API 598,DIN 3230,EN 12266-1,GOST 9544,BS 6755-1,BS EN 12266-1,BS 5146

End Connections

Raised Face, RTJ, Threaded, Socket Weld, Threaded X Socket Weld

Face to Face

ASME B16.10,EN 558-1,GOST 9544,BS EN 558-1,DIN 3202

Options

NACE Compliant

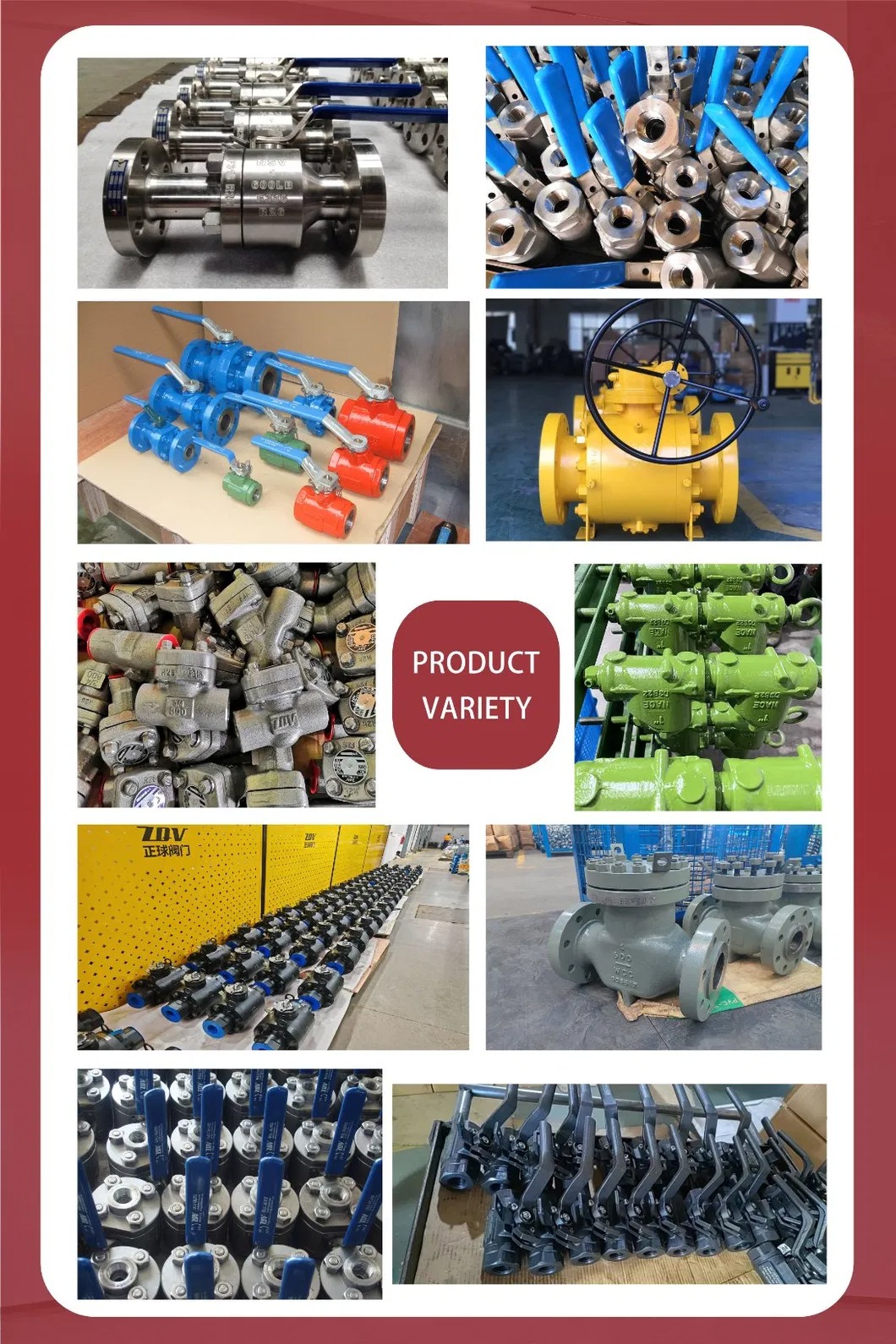

Description

Application

Petroleum, chemical industry, pharmacy, fertilizer, power industry etc.

Advantage

1.Bellow seal element. The key part of bellow sealed globe valves is mental bellow. It is the connection between cover and stem with automatic roll welding. The mental bellow can keep the stem part no leakage.

2.Benefit from the con and streamline shape design, the disc has a reliable seal and longer service life.

3.Double seal design(bellows+packing). Bellow and packing can protect against leakage and provide a excellent seal.

4.Grease nipple. It can direct lubricate the stem, nut and sleeve.

5.Ergonomic hand wheel. It provide longer service life and easier operation.

Technical specification

Design standard: DIN 3356

Face to face dimension: DIN 3202

Flanged ends: DIN 2543-2545

Test & inspection: DIN 3230

Performance specification

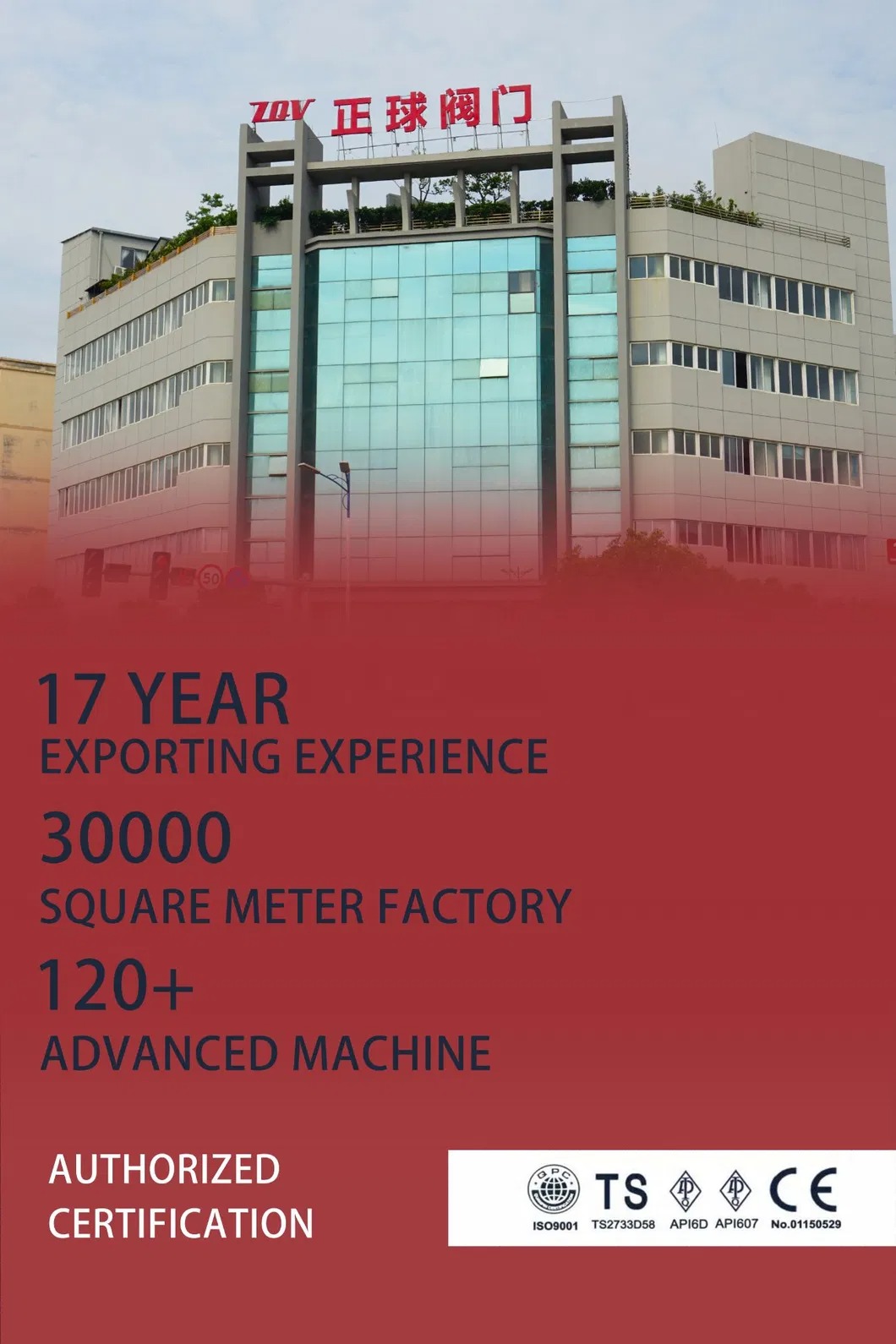

Factory Show